What Work Has Been Completed On The First Mine?

The following assessment work has been performed on our Oro Gold Mine in Arizona:

United States Bureau Of Mines Testing 1994:

- Testing by the United States Bureau Of Mines:

- (USBM) report United States Bureau Of Mines Test Program # 14 showed as high as 7.17 OPT AG (Silver) In USBM MLA 24-94 (316 Pages; 21.8 mb):-94 in a 1994 open publication on this historic mine area. Bloomberg Report on USBM Data: http://www.bloomberg.com/apps/news?pid=newsarchive&sid=aVxbcurOEqa8

- According to USGS data, the average grade was 0.3 ounces of gold per ton and 0.5 ounces of silver per ton.

- 25 samples Taken

- Highest .87 AU oz/ton

- Audit Assay .35 AU oz/ton

- The highest grade silver sample BM14 (246 g/Mt – 7.17 oz/Mt)

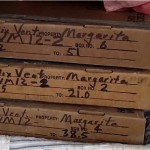

- Re-Core Sample Program-done in 1996:

Red Dog Drilling 1996 (Map re-drawn 2009):

100 hole percussion core sample program as deep as 385 feet close spaced approximately 50 feet apart showed higher AU oz/ton then 36.78 acre test shown below. This core sample program showed an identified deposit with demonstrated potential but not a proven reserve defined ore body since it was not done to International ISO/IEC 17025-2005 standards. Our mining engineers say we could do a bulk sample for low cost at narrow intersects and test by pad/cyanide on site to show the area as provable/minable but not as a proven reserve. They also said we should be able to utilize drill collars to do a prove drill program to identify each hole and do an audit assay to NI 43-101 reporting standards tying in this core sample data to demonstrate

reporting standards tying in this core sample data to demonstrate an expanded reserve.

an expanded reserve.

Hellix Ventures Drill Program(HELLIX VENTURES INC. (HEL:TSX.V / HLLXF:OTC) -Vancouver Rotary Drilling program January 2012:

Hellix Ventures Drill Program(HELLIX VENTURES INC. (HEL:TSX.V / HLLXF:OTC) -Vancouver Rotary Drilling program January 2012:

The physical core samples that we obtained with the purchase of the mine are stored in Nogales near the mine for easy access by our mining engineering staff and a prove drill tie in may cost around $35,000.00.

The program entailed twelve vertical HQ size diamond drill holes to a maximum depth of 100 feet to confirm historic near surface test results for a total of approximately 1200 feet of diamond drilling to assess gold mineralization in four main target areas. The test area was a 2000 ft N-S by 800 ft E-W (610 meters N-S by 244 meters E-W) section of the entire 1,632.14 acre mine or around .06 sq mi or approximately 36.78 acres.

The samples were taken to an accredited laboratory recognized to International Standard ISO/IEC 17025-2005 in Tucson, Arizona. Gold analysis was done using a combined process of Fire Assay pre-concentration followed by an Atomic Absorption finish. This is considered industry accepted procedure.

The samples were taken to an accredited laboratory recognized to International Standard ISO/IEC 17025-2005 in Tucson, Arizona. Gold analysis was done using a combined process of Fire Assay pre-concentration followed by an Atomic Absorption finish. This is considered industry accepted procedure.

Initial assay procedure: (Test # 1)

Core samples were collected, selected, handled and delivered to the laboratory in Tucson, Arizona by an independent Registered Geologist in charge of the QA/QC program on this project. Sample procedures were followed that meet the requirements for NI 43-101 reporting. Standards and blanks were inserted at prescribed intervals in each hole as well as a second re-sample of one reject material interval from each hole. Standards were provided from a reputable independent geochemical contractor. This was in addition to the Tucson labs independent internal standards for QA/QC procedures.

Check audit assay procedure: (Test # 2)

For check assays, select pulp samples were shipped from the laboratory in Tucson, Arizona directly to an ISO accredited lab in Reno, Nevada by the Tucson lab’s employees as requested by the previous claim optionee. The Reno, Nevada laboratory tested the pulps for gold via fire assay with gravimetric finish. Two standards and one blank were included for QA/QC purposes.

Final audit assay procedure: (Test # 3)

For the audit assays, select pulp samples from all holes were shipped from the initial assay lab and the check assay lab to the third test facility in Canada (an ISO accredited lab) as requested by the previous claim optionee. The pulps were tested for gold via fire assay with gravimetric finish. Standards and blanks were included in pulps for each hole for QA/QC purposes by the previous claim optionee in addition to the lab’s independent internal standards for QA/QC.

Final: (0.35 AU oz./ton) in the combined audit assay.

GoodMark Capital Group, Inc 81 Assay Testing Program And Gravity Concentration Test:

NORTH STAR MINING GROUP SURFACE SAMPLING REPORT and Assay data GMCG Oro Gold Mine rev070915

Final: (0.47 AU oz./ton) in the combined productive sample assay average.

ASSAY AVERAGE ON PRODUCTIVE SAMPLES WITH A CUT OFF RATE OF (.005) OUNCES OF GOLD PER TON OF RAW MATERIAL NOT INCLUDING TRACE SAMPLES SHOWED (.477731707 ) OUNCES OF GOLD PER TON OF RAW MATERIAL. ( Average of approximately $429.96 worth of gold net PROFIT per 2,000 pounds of raw ore material ) ASSAY AVERAGE ON PRODUCTIVE SAMPLES WITH A CUT OFF RATE OF (.005) OUNCES PER TON GOLD ALSO INCLUDING TRACE SAMPLES SHOWED (.241814815) OUNCES OF GOLD PER TON OF RAW MATERIAL. ( Average of approximately $216 worth of gold net PROFIT per 2,000 pounds of raw ore material )

Past Historic Assay Testing And Drill Programs That Have Been Performed On The Property.

Posted in: General